Got the smaller gauges fitted and happy with the results, I won’t have to trim anything off the cluster structure assembly like I had originally thought I might have too. The compact nature of the speedhut are a big plus here. Nothing special needed, simply enlarge the factory holes is all that is needed.

I only need to find a solution to retaining the brake warning light which will probably involve adding a light somewhere(maybe the xr7 switch holes)

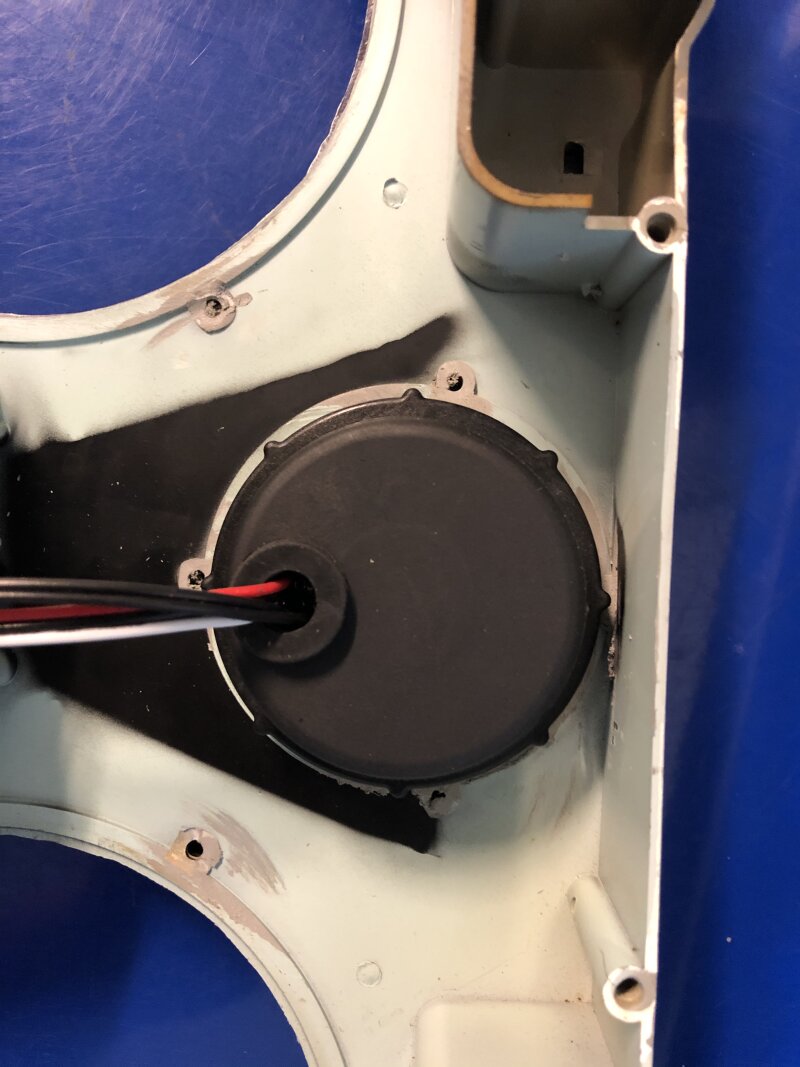

Can see some of the needed trimming here, mostly just the tabs that hold the original lense in place.

Gauge does not stick out too far either,

I’ll work on wrapping the face plate and painting the cluster face this week.