I just had to remove my TL 4 spd for about the 10th time in the last year and a half for a problem with my McLeod hydraulic throw out bearing. ![]()

After installing a new one a little over a year ago because the previous generation one I was trying to use kept leaking like a sieve and even after a factory rebuild it still didn’t work right I got fed up and bought a brand new one to use. It lasted for driving the car an average of once a week over the last year having to bleed the system twice in that year.

This time is the last straw. It would not disengage the clutch completely a couple of days ago and got worse as I traveled home. It turns out the top bleeder hose worked its way loose and sucked in a bunch of air at the fitting on the unit.

This is the absolute last time I will remove the transmission for this POS bearing unit.

I am converting to an external slave unit and need to know if anyone else has already done this on a TL 4 spd. I am going to have to FAB up a bracket for the slave unit to either push or pull the original clutch fork and really don’t want to reinvent the wheel. If you have done this, did you use a push or a pull type slave cylinder?

In a fit of anger, I ordered all the parts I need and got a push style slave cylinder from Speedway, but I am thinking I might have to use a pull type because of the exaust pipe that might be in the way. I’ll know for sure when the part gets here tomorrow, but wanted some feedback first.

Talk to Modern Driveline.

I have the modern driveline external slave setup on the road race Cougar. Mounted on the TKO6 but, same concept as the TL4 pushing on the fork. I didn’t want any oil leaks getting oil onto the clutch is the reason I went with the external slave. Easier to maintain if you have a problem as your unfortunately finding out. Only concern I had was heat from the header next to the slave. But, so far that hasn’t been an issue. Also have the over center linkage on the clutch pedal which makes the clutch feel and pressure just right.

I have an external push type, as well. Seems to work just fine next to the exhaust.

I used MDL’s LF series master: http://www.moderndriveline.com/catalog/ford-hydraulics.htm

And just a generic CNC brand slave. http://www.cncbrakes.com/sc.asp?grp=sc&subgrp=push&series=305&subseries=

I did have to fab up my own mount since I kept my toploader bell:

I have the MDL master on mine as well and it has worked flawlessly. Thanks for the pics of your external setup. Your external slave looks very similar to the one I ordered. Your pics show that I should have room to mount mine without the exhaust interfering.

I wish I would have done the external route in the first place, it would have saved me a lot of time, money and aggravation.

Thanks again.

I will post pics of my new setup when I get all the parts in and installed.

I neglected to say, I had to have two holes drilled and tapped into my bell housing for the spacer/cylinder mount to bolt into. That was fairly simple, as i just marked where I needed it to sit, and had my father in law do it at his machine shop.

Also, “if I did it over again”, and if I was any good at tube flaring, I’d make my lines hard lines, instead of the flexibles. That would allow even better routing to keep away from the exhaust.

I don’t think you want a hard line to your slave cylinder as the motor twists a little while driving and a hard line won’t give enough to withstand that motion. Best to have a flexible line from the master to the slave cylinder since its mounted on the motor/bell housing.

Anyway. My slave cylinder arrived in the mail yesterday so now I can fab up my bracket and get to installing soon.

I’ll post pics once complete. Thanks again.

You know, I hadn’t thought of that…good thing I’m no good at tube bending/flaring, then! ![]()

Well I started making the mounting bracket today. It will be a bit more complicated than the bracket MO2872 used as I have to clear my headers/exhaust pipe. Here is a pic of the brass fitting that worked it’s way loose. I am not sure if it can be tightened back up. It did not come loose from the hose, but pulled out a little from the bearing body and it now swivels freely.

TO bearing by 69xr7ragtop, on Flickr

Pics of my convoluted bracket will follow once I complete it’s construction.

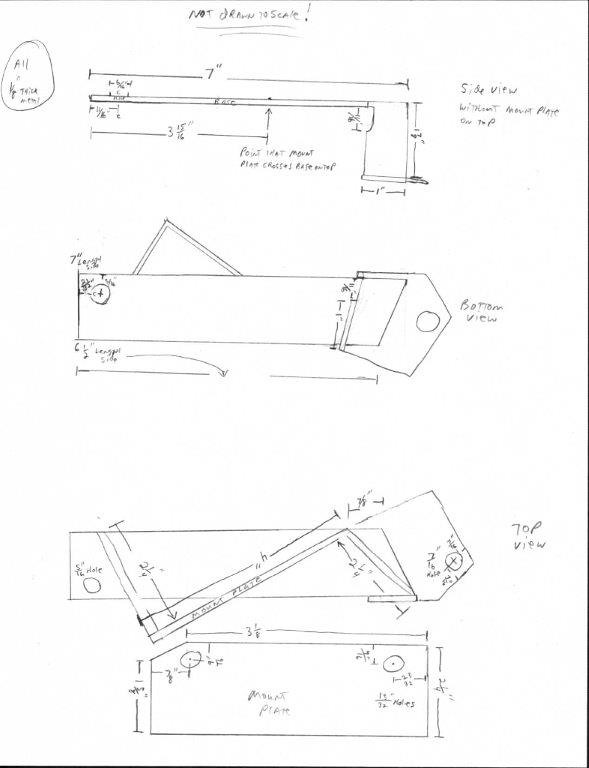

Pic of my over-engineered bracket for the top loader 4 speed. I still have to weld everything solid and add at least 4 additional gussets to make it nice and strong. The bolts just laying in the holes are where it bolts to the transmission using original holes. My goal was to make something that could withstand the continual force of pushing the clutch fork and be able to remove it and bolt right up to any TL 4spd. More pics to follow after I finish the gussets and the welding / painting. I will also upload a pic of it installed so it will make more sense how it bolts up.

I had to angle the slave cylinder so it would clear my exhaust. (the reason the mounting plate is angled and not square)

slave cylinder bracket TL 4spd by 69xr7ragtop, on Flickr

Have you discussed with McLeod all the problems you had? That really should be a good reliable unit.

Funny you should mention talking with McLeod on their hydraulic units. The first one I used was a Gen 1 that was used when I got it. I could never get their banjo fittings to seal up correctly so I ended up drilling and tapping the fitting holes and installing new fittings and hoses. I ended up sending it back to them for them to rebuild because the internal o-rings leaked. When I got it back and installed it, it still leaked and was useless junk. I spent the big money on the new Gen 3 one and installed it. It worked using the car a couple of times a week for a little over a year until this latest issue with the top fitting working it’s way loose somehow. I am fed up and will not purchase anything else from them…ever. Just my 2 cents. I am sure there are others that have never had an issue with their products and I’m also sure there are others like me that have nothing but issues with them.

That’s actually quite brilliant, if it works the way I’m picturing…well done.

OK, I finally got the bracket finished and installed. Another hour of work and I should be able to drive “mistress Jessica” again. ![]()

IMG_3348 by 69xr7ragtop, on Flickr

IMG_3353 by 69xr7ragtop, on Flickr

clutch slave mounting bracket by 69xr7ragtop, on Flickr

The drawing was the best I could do with the time I had available. My wife was not being very patient with me while I was working on it. She’ll get over it eventually.

After installing the exhaust, it is a little less than 1/4" from the slave cylinder so it is tighter than I really want, but it will do.

Looks good from where I’m sitting!

Thanks! I’ll let you know how it works when I finally get some more time and can finish buttoning everything up.

The use of existing holes is great, and I had that same thought when doing mine…but what I didn’t have at the time, was a welder! I DID, however, have a father in law with a machine shop. So, took him my bell and said “Drill and tap here”…“please”…LOL.