I wonder why I haven’t received any notifications for all of these replies?!

Things are coming along ok though. I decided that since this car is probably never going to see any kind of concourse restoration (too much effort to fix the rust, remove the cage, etc etc…all for a 2bbl 302 XR-7 lol), I wouldn’t go through the hassle of butt welding in the floor pan. What I DID do, is trim it to fit properly (meaning overlapping), coated all the overlap area with a weld through sealer I got from the guy who welds all of our large diameter cement lined water pipe together, then welded both the inside of the car, and the outside. I then drilled a boatload of holes (more detail on that below) through the new floor pan and the flange on the subframe, and rosette welded all of those back closed. After that, I smothered all the seams inside and out with Sikaflex 1a…then coated with a rust preventative paint. Here’s a few pictures:

Cut out all the rust…

Test fit the (rather crappy) reproduction patch panel…it needed trimmed substantially to even come close to getting the stamping to line up. I finally cut the entire toe board section out, which helped tremendously.

Next, I wire wheeled the crap out of EVERYTHING, then sprayed on the sealer…then coated that with the rust preventative paint…refit the panel, and welded it in. My method for welding it was kind of crude, but it was also incredibly effective. What I did, was screwed the entire panel in with self tapping screws…starting at the door first, and working my way over to the tunnel. I also screwed through to the frame flange as well. I then welded the perimeter (I hate welding sheetmetal…I learned this long ago welding a sump onto a fuel tank…), and one by one removed the screws and rosette welded those holes as well. The screws held everything dead tight, and didn’t allow anything to move or warp. I was pretty freakin generous with the screws, lol. I figured the more holes in it, the stronger it’d be.

All sealed up. Sikaflex is great stuff, lol. It’s a polyurethane elastomeric sealant, stick to anything, will cure under water…and never fully hardens. Pretty cool.

The finished job. Not the prettiest, but its solid as all hell, and will more than do the job I require of it. I’ll address the heater core and cowl vents to make sure they weren’t the cause (and fix them if they were) at a later date.

So now…on to my next issue. Wheel/tire fitment.

As I mentioned earlier…my wheels are 15x9 with 6.5" backspacing. The current tires are 26x10.5 slicks. This combination did NOT work. Even after cutting the excess metal off of the snubber bracket they wouldn’t fit.

Pesky leaf springs…

Anyhow, I ordered some relatively nice 1.25" wheel spacers, thinking this would be just the fix, and for the driver’s side (which was the side I test fit everything on), it absolutely was, the outer edge of the tire bulge was about even wit the inner body line of the wheel opening. A nice rolling of the inner lip and it would be perfect. The passenger side however, was now sticking out of the wheel well by a fair margin (even some of the contact patch). At this point I was thinking the rear end was installed incorrectly. Possibly that the Granada/Monarch/Versailles perches had a larger locating hole in them…and that whoever did the install just didn’t center it. Wrong. After loosening the u-bolts and being forced to pry the rear end from the pinion angle wedges…it was very apparent that the locating holes were precisely the right size. So I pulled the rear end, and started in on everything with a tape measurer. Turns out, the rear end is fine. Everything is properly centered from the wheel mount face to the spring perch. So, what’s the problem you ask?? Well…it appears that THE CAR is freaking offset on the rear subframe by almost an ENTIRE INCH. Seriously :l. The passenger side outer wheel opening is literally 7/8" closer to the leaf springs (which are mounted very solidly to the frame on both sides I might add) than the passenger side. This means I’m going to have to pick up a smaller wheel spacer for the passenger side, which is really just kind of silly. I mean…I don’t know if this is common with Cougars…but I’ve owned five separate 67 Mustangs, all utilizing 10" rear wheels…and never had this problem.

Have any of you had that kind of issue with these cars? How did you fix it?? Was it able to be fixed…? Kinda sucks!!

Anyhow lol, here’s a picture of how the current wheels and tires look on the driver’s side. Not bad…but a bit short in my opinion. Good thing I’m probably going to be switching to a 28" tire anyhow, which will help fill the wheel well some.

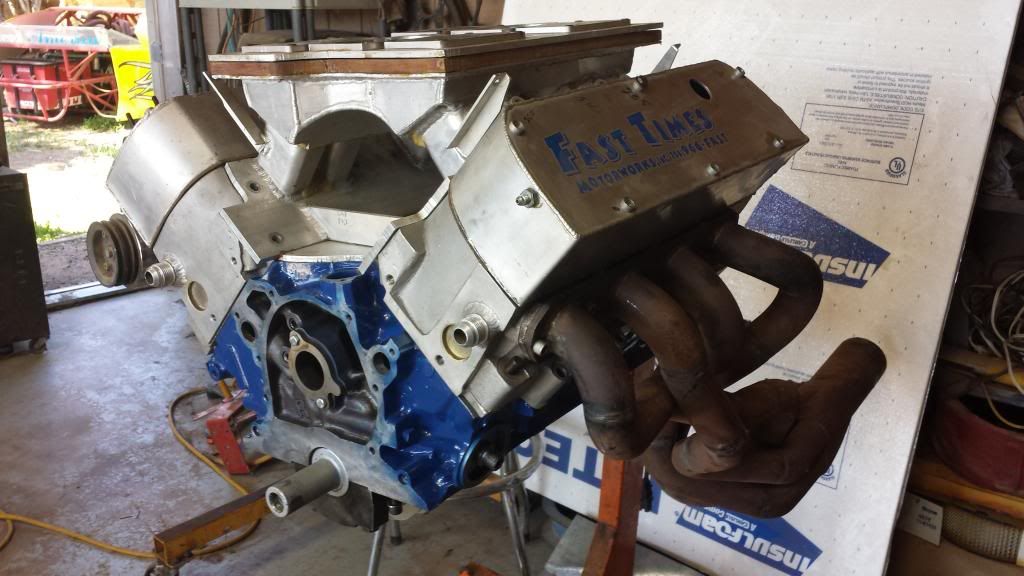

Anyhow, this is where it sits. Tomorrow I’ll be pulling the 351 out, and cleaning the engine compartment. If it needs resprayed I’ll go ahead and do that too…but it actually looks pretty well done…just dirty.

More pictures to come!